BiDiB is designed to control model railways, as there are control of locos, accessories and safe transmission from feedback information out of the layout to a connected PC. BiDiB is short for Bidirectional Bus and has the following advantages:

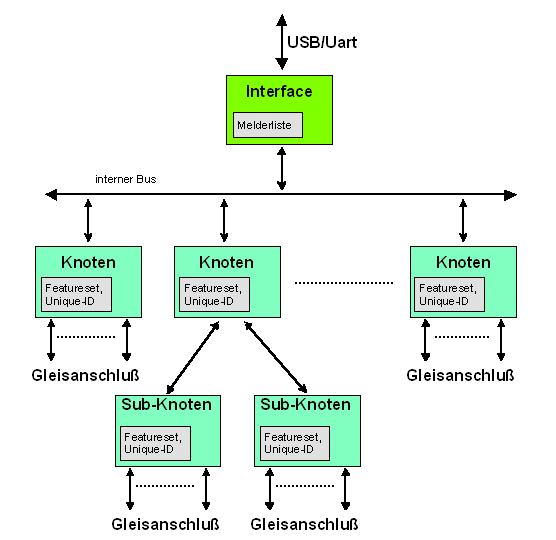

The above picture shows a typical arrangement. The protocol is suitable for different feedback systems and can manage simple home layouts up to large exhibition layouts. The Protocol can be easily adapted to nearly all requirements. For this purpose, there is a mandatory set of query and setting parameters existing that must be implemented in every feedback system. The following used terms will be summarized and explaned in the glossary.

Lenz and Tams introduced BiDi feedback systems by 2009, therefore the use of bi-directional data transfer between DCC decoders and control units was theoretically possible. Suitable feedback systems has been announced, but by the end of 2010, only the simple Tams RC Talk was available in the market. From the discussion about a future proof successor, the BiDiB protocol was created. This was the base for an enhanced draft, which also includes command stations, accessories and control panels.

At this point, I would like to say "Thank you" to my discussion partners, Mr. Tams, Mr. Bluecher and Mr. Herzog for their constructive input.

BiDiB® is maintained and developed further by a working group (BiDiB-Implement-Group). Among other, the sirs Kersten Tams, Markus Herzog and Wolfgang Kufer are authoritative members of this group.

Legal: This specification is provided "as is" and without any warranty of any kind, expressed or implied. Without limitation, there is no warranty of non-infringement, no warranty of merchantability, and no warranty of fitness for a particular purpose. all warranties are expressly disclaimed. The user assumes the full risk of using this specification. In no event shall any member of BiDiB-Implement-Group be liable for any actual, direct, indirect, punitive, or consequential damages arising from such use, even if advised of the possibility of such damages.

BiDiB is intended for use with model railroad control software and may be implemented without license costs at the PC side as well as on the hardware side. To ensure compatibility, the following license terms & conditions have to be observed:

This document describes revision 1.29 of BiDiB, updated June 21, 2023.

This document describes the basic message structure. Messages that are specifically associated with an application (e.g. switching, detection, driving,...) will be described in other documents or chapters.

| 1.29 | 2023-07-21 | added:

|

| 1.28 | 2020-05-31 | protocol version 0.6⇒0.8: streaming for features and accessories. added: extensions for DCC commands (F29…F68, DCC-SDF, analog command), preparations for automatic logon with DCCA, query of active locos, load type configuration for ports, global address detection, transport of debug outputs, explanation on local messages |

| 1.27 | 2017-04-07 | added: position reports, BiDiB system time, porttype SWITCHPAIR, configuration fingerprints, accessory emergency stop, accessory details |

| 1.26 | 2016-08-15 | added: BIDIB_ACCESSORY_PARA_STARTUP, BIDIB_ACCESSORY_PARA_OPMODE. Rework of all parts, explanations and clarifications. |

| 2016-02-25 | revised port control, added MSG_LC_PORT_QUERY_ALL, protocol version 0.6⇒0.7 | |

| 1.25 | 2015-11-28 | revised byte order of port addresses in the flat model |

| 1.24 | 2015-03-22 | added MSG_CONFIGX_GET_ALL, flat port model (see port control), protocol version 0.5⇒0.6 |

| 2014-12-04 | added new macro command FLAG_QUERY0 | |

| 1.23 | 2014-11-11 | add new configuration messages for ports (CONFIGX*) |

| 2014-08-14 | additional defines for POM (DCC generation) | |

| 2014-07-25 | additional items in the licence section | |

| V1.22 | 2014-06-26 | added: BIDIB_MSYS_SERVOMOVE_QUERY, longer responses for version queries |

| V1.22 | 2014-02-07 | added: MSG_ACCESSORY_NOTIFY, MSG_BM_DYN_STATE, MSG_CS_PROG, MSG_CS_PROG_STATE |

| V1.21 | 2013-12-16 | added: MSG_STRING_GET, _SET, MSG_STRING, FEATURE_STRING_SIZE |

| V1.20 | 2013-11-18 | added hints and explanation for turntables; BIDIB_CS_STATE_GO_IGN_WD |

| V1.20 | 2013-10-29 | added MSG_SYS_GET_UNIQUE_ID mandatory for standalone bootloader |

| V1.19.1 | 2013-10-21 | Translation from speed to DCC28/DCC14 now mandatory, formula and example added |

| V1.19 | 2013-10-04 | MSG_LC_OUTPUT_QUERY added; new features: FEATURE_RELEVANT_PID_BITS, FEATURE_CTRL_PORT_QUERY_AVAILABLE new: BIDIB_MSYS_ACC_OKAY_QIN1, BIDIB_MSYS_ACC_OKAY_QIN0, BIDIB_MSYS_ACC_OKAY_NF |

| V1.18 | 2013-07-18 | Additional responses to GET_SYS_MAGIC (Support for tiny bootloader). Added SecureSwitch definition to accessory |

| 2013-06-29 | Update of licence conditions | |

| V1.17 | 2013-06-18 | Introduction of a watchdog for DCC generation, added FEATURE_GEN_WATCHDOG |

| V1.16 | 2013-06-02 | more details on MSG_SYS_RESET, added FEATURE_CTRL_STRETCH_DIMM |

| V1.15 | 2013-04-20 | added transmission of error codes for accessory |

| V1.14 | 2013-04-02 | unified definition of switch time |

| V1.13 | 2013-03-25 | MSG_LOCAL_LOGON_REJECTED added. Error handling in case of too much participants |

| V1.12 | 2013-02-23 | MSG_BOOST_CURRENT will be replaced with MSG_BOOST_DIAGNOSTIC. |

| V1.11 | 2013-01-30 | Parameter added for MSG_BOOST_ON and _OFF |

| V1.10 | 2013-01-23 | MSG_CS_BIN_STATE completed |

| V1.09 | 2013-01-17 | FEATURE_BST_INHIBIT_AUTOSTART completed |

| V1.09 | 2012-12-21 | Explanations for MSG_CS_DRIVE_ACK; MSG_BOOST_QUERY completed |

| V1.08 | 2012-11-13 | Explanation and final coding for MSG_BM_SPEED, FEATURE_BM_ISTSPEED_INTERVAL |

| V1.07 | 2012-10-12 | Supplementation of the class accessory, Parameter at MSG_STALL; Explanation for MSG_CS_DRIVE |

| V1.06 | 2012-09-26 | Accessory class: MSG_LC_WAIT added, Spelling corrections. |

| V1.05 | 2012-09-24 | Occupancy class: Additional commands MSG_BM_GET_CONFIDENCE and MSG_BM_CONFIDENCE. |

| V1.04 | 2012-07-25 | Additional explanations for MSG_VENDOR*. MSG_SYS_PING / MSG_SYS_PONG got a new parameterp Supplementation for switch class: BIDIB_MACRO_RESTORE, BIDIB_MSYS_DELAY_RANDOM, MACRO_PARA now 32 Bit. |

| V1.03 | 2012-07-25 | Additional explanations for MSG_VENDOR*. |

| V1.02 | 2012-06-06 | Explanation for MSG_NODE_LOST corrected. |

| V1.01 | 2012-03-19 | MSG_FEATURE_GETALL, MSG_FEATURE_GETNEXT, MSG_NODETAB_GETALL, MSG_NODETAB_GETNEXT, Transmission process for Features und Nodes explained. |

| V0.13 | 2012-02-21 | MSG_BM_ADDRESS with opportunity to report multiple occupancy. reference at MSG_BM_SPEED. |

| V0.12 | 2011-07-20 | Local command for PING and PONG added; MSG_BM_MIRROR_OCC and _FREE added. |

| V0.11 | 2011-07-20 | New feature-parameter for Booster, system time, MSG_BOOST_STAT messages extended. Current setting for booster added. |

| V0.10 | 2011-04-02 | Suggestions for decoder registration added, new message MSG_BM_BLOCK_CV for block reading of CVs.. |

| V0.09 | 2011-02-24 | Changes at the NODE_TAB (in case of no sub-nodes), more failure codes added. MSG_SYS_GET_ERROR added. |

| V0.08 | 2010-12-20 | Booster class completed. |

| V0.07 | 2010-12-07 | Explanations for Vendor config, V_VALUE added; failure messages extended; MSG_SYS_MAGIC with index 0;

Enable /Disable with auto-forward to sub-nodes. BM_MSG for accessory added. MSG_SYS_IDENTIFY_STATE added. |

| V0.06 | 2010-12-06 | Explanations for NODE_CHANGE added |

| V0.05 | 2010-12-01 | Unique-ID explained, PKT_CAPACITY new added, ClassID added |

| V0.04 | 2010-11-29 | Packet structure for routing optimized, Fine tuning. new added: MSG_BM_SET_SIZE, MSG_BM_GET_SIZE |

| V0.03 | 2010-11-25 | Extension for hubs and sub-nodes. |

| V0.02 | 2010-11-17 | Extension for heterogeneous feedback modules, Individualisation of feature sets for single modules |

| V0.01 | 2010-11-03 | Initial document |

BiDiB is designed as a stateless protocol. There exist several safeguards to deal with message losses.

The most important property to achieve a high error tolerance is the idempotence of the messages. Generally messages transmit states, not commands or orders. Their reception is typically acknowledged by the node with a message of equal content. Thereby the transmission can simply be repeated in case of an error, without causing undesired actions when received multiple times. This holds in particular for the critical model railroad applications driving, controlling and feedback. An identifier is always used in sequential transmissions with multiple messages, so that missing information can be requested again.

Communication errors on the other hand are reported once only and not repeated, which simplifies the implementation. A loss of an error message can be handled the same way as the absence of the regular answer. If multiple errors occur together, they can be put in a queue to be retrieved, but they don't have to be repeated either. If an error persists, it simply is reported again at the next attempt of using the object. A recovery from an error is generally not reported. Some objects where fault/error conditions are intrinsic (e.g. boosters and accessories) constitute exceptions hereof, retention or repetition might be required for them.

Likewise dealt with are spontaneous events that are not mission-critical. The loss of such messages can only be detected by checking sequence numbers, but there is no mandated error handling and no way to retransmit the message. For operation critical events (Occupancy, Accessory) there are acknowledgement mechanisms "Secure-ACK" and "Secure-Switch" as safeguards.

The continuing revolution of BiDiB is deep-seated in the protocol. Rigorous attention is paid to backward compatibility of new revisions of the specification. Extensions to the functional range are usually readily possible, as they are typically optional and can be ignored. In case of backward incompatible changes the protocol version is incremented, which can be retrieved from every node. This does allow the support of out-dated implementations and even assures the compatibility with unknown functions to some degree.

The following terms for each protocol participant or properties will be used in this document:

| BiDiB: | The protocol standard, the way how messages are encoded. |

| BiDiBus: | One possible physical implementation, specially for wired connections within a model railway. BiDiBus is based on RS485 and uses RJ45 cables. |

| Bus system: | The complete setup, consisting interface and nodes (i.e. detectors) + possibly internal connections. |

| Class: | Nodes are divided in classes, depending on their basic properties. There are as example: occupancy detectors, DCC Generators, Switch outputs, Track panels. |

| Detector: | A single node within the BiDiB system which is able to detect track occupancy and recognize BiDi feedback signals. |

| Feature: | Particular property of a node (e.g. 'detector can recognize loco direction'). Features can be queried and configured individually. |

| Host: | The control computer, usually a standard PC with appropriate software. |

| Hub: | A node in one level of the bus system, which is also an interface to the next lower level. |

| Interface: | The location within a level (structure) in the bus system, which communicates with the host or parent-node. |

| Logon: | The attempt of a node to get a logical connection to an interface. The logon is acknowledged and the host is notified about the change. |

| Node: | A subscriber inside the BiDiB system (occasionally distributed) hardware. A subscriber within a level might be also an interface for the next sub-level (Hub-functionality). |

| Unique-ID: | The globally biunique node identifier. It contains the announced classes, the manufacturer code, and a vendor-specific number derived from the hardware ID. |

| Node-address: | The automatic assigned number from the interface (byte), under which the node is (at this level) addressed in this session. (NODE_ADDR) |

| Magic: | A (meaningless) number, which will be queried by the host during interface startup. For example the correct baud setting can be recognized. (=system id) |

An system addressed with BiDiB is organized like folders: The host provides an interface that allows it to establish a communications link and the interface allows him access to a (flat) array of nodes. Each of these nodes is usually a component that contains a particular function (for example, a detector with feedback contacts). But it is also possible that this block itself is an interface too, which holds a further structure (like subfolders). This achieves high flexibility in wiring possibilities and also in the heterogeneity of the connected detectors.

BiDiB is able to assign addresses automatically to nodes. Each node has an unique manufacturer-programmed number that is part of the Unique-ID. During startup of the feedback system, the interface searches existing nodes within its structure and assign a local address to each node. This address has the length of one byte. The interface builds a assignment table with all available nodes, their Unique-ID and their local address. Nodes itself can be also interfaces which gives a threaded structure. The maximum address length within the thread is 4 bytes.

This assignment table is different on each startup and will be automatically extended if a new node is added to the bus. In this case, the interface transmits a message to the host.

Internal to the host, the nodes are also stored with their unique ID, besides the program-specific things like screen position and node name. The host will retrieve the mapping from the interface during startup and gets the valid local addresses for this session that belongs to the unique IDs. The mapping between the object on the user interface and the model hardware is done through the node identity and is therefore independent from the current address assignment.

To facilitate the replacement of nodes, it should be minded in host programs that the Uniqued-ID assigned to a node object can easily be exchanged for another one. Because the unique ID of a device cannot be set by the user, they cannot program the replacement node to the "old address" to continue using the mapping configured in the program; instead it is necessary to make the change within the host software. The swapping of the unique ID is needed for instance when replacing a defective device by a identically constructed one, when upgrading hardware to a superior product with more outputs, or when deploying a different product firmware for more functionality.

BiDiB protocol is suitable for different transmission media such as serial connection, USB, RS485, Ethernet or wireless (with an adapted framing for each media). For specifications, refer to the respective documents.

The respective physical layer ensures the correct framing and bytewise, transparent transport of BiDiB message packets. The transfer layer must secure the transport of the data with CRC. The transfer layer must at least be able to transport messages with a size of 64 bytes.

CRC means the CRC8-Byte; On the transmitter side, the polynom x8 + x5 + x4 + 1 will be generated over the message, starting at the first byte from the message, Init=0, none inverted. On receiver side, the CRC with the same polynom will be generated over the whole message including CRC. The result must be 0.

A MESSAGE is structured as follows:

MESSAGE ::= MSG_LENGTH MSG_ADDR MSG_NUM MSG_TYPE DATA MSG_LENGTH ::= 0x00 | … | 0x7f MSG_ADDR ::= MSG_ADDR_STACK 0x00 MSG_ADDR_STACK ::= ε | NODE_ADDR MSG_ADDR_STACK NODE_ADDR ::= 0x01 | … | 0xff MSG_NUM ::= 0x00 | … | 0xff MSG_TYPE ::= 0x00 | … | 0xff DATA ::= ε | ANY_BYTE DATA ANY_BYTE ::= 0x00 | … | 0xff

A message contains the length, an address specification, a (consecutive) message number, a type specification and optional parameters. These fields are described below:

| 0x00 | Offset for downlink messages |

| 0x80 | Offset for uplink messages |

| 0x00 | Offset for system messages |

| 0x10 | Offset for feature and user messages |

| 0x20 | Offset for feedback detector messages |

| 0x30 | Offset for booster messages |

| 0x38 | Offset for accessory, switch and macro messages |

| 0x60 | Offset for DCC generator messages |

| 0x70 | Offset for local messages (with special rules, see below) |

The data securing against transmission errors is the responsibility of the respective transport medium (e.g. CRC in case of serial transmission). The protocol itself doesn't provide message retransmit, critical messages are secured at a higher level (e.g. with Secure-ACK or corresponding response of the node).

The message length (MSG_LENGTH) does not only delimit messages where multiple are sequenced back-to-back, but also specifies how many DATA bytes are actually available as message parameters. This might indeed be more or less bytes than the message type suggests. Thereby optional parameters can be accomplished that are set to default values if not existent. If less parameters are sent than necessary, the node responds with an error message. If more parameters are sent than expected, the surplus bytes are ignored; this assures forward compatibility.

A message may have a length up to 64 bytes (MSG_LENGTH=63), all transport layers need to support these. Longer downstream messages can, as long as supported by the respective transport layer and node, be allowed per node via the MSG_PKT_CAPACITY message. To send a long message to a node, all interfaces on the transport path have to support this as well. Longer upstream messages shall be limited in accordance with the lengths used in the downstream.

BiDiB allows to wire subnets and connect them in star topology via hubs (similar to USB). This provides scalability for large model layouts. For smaller layouts, probably only one network will be build and therefore the information in this chapter can be skipped for now.

Local address assignment in sub-networks is described in a further document For the protocol description, only the results of this process are relevant.

A maximum of 4 cascaded networks is allowed. This limitation is intended to facilitate host implementations, thereby the respective current local address of a endnode is limited to 32 bits.

The following rules apply for the routing of messages:

To enable the parent node, respectively the host, to detect this structure, appropriate commands are existing:

If there is a change in the assignment table during operation (e.g. connect or disconnect), the interface sends a MSG_NODE_LOST or MSG_NODE_NEW message anyway. This message must be acknowledged by MSG_NODE_CHANGED_ACK (or a complete node table query). Both messages MSG_NODE_LOST, MSG_NODE_NEW and also MSG_NODE_CHANGED_ACK have the (continuous) version number of the table as a parameter. This ensures that all changes at the bus structure will be recognized.

Changes in the node table should be avoided by the interface (e.g. transmit no logon request). If there is a change in the node table while being queried and transmitted with MSG_NODETAB_GETNEXT, the interface must start over again with the transmission of a new MSG_NODETAB_COUNT (but with an incremented version number).

Each node has a distinct identifer, this number is called Unique-ID. The Unique-ID contains 7 bytes:

| 1. Byte | ClassID

This is a bit field indicating the class membership of this node. A node may also belong to several classes at once. The classes serve as a quick reference for the host about which functionalities can be found on this specific node. To rapidly locate a feature-based subfunctionality it is enough to only query the nodes which have set the corresponding class bit. If a node has implemented commands of a particular class, the appropriate class bit must be set as well. Conversely, it must know the commands of the announced classes and answer them correctly. Even if in the current configuration no objects are available, it should register the class and yield 0 for the count.

Reserved bits must be coded as 0. | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2. Byte | ClassID Extension; this byte is reserved and must be coded with 0. | ||||||||||||||||

| 3. Byte | Vendor-ID: The same coding as DCC is used here, see NMRA Manufacturer ID Numbers. | ||||||||||||||||

| 4.-7. Byte | Product ID, comprising of 32 Bit.

These 4 bytes (= 32 bits) are split into a product identifier (lower 'p' bits) and a serial number (upper 's' bits). This allows for an easier identification of nodes by analysis tools and host programs. The coding in BiDiB is always little-endian (low-byte first), the product identifier starts at bit 0, first byte. It is up to the vendor, how many bits he uses for product and for serial number. However, a default of 16 bit / 16 bit is recommended. The feature FEATURE_RELEVANT_PID_BITS defines, how many bits are used for product ('p'). If the feature FEATURE_RELEVANT_PID_BITS doesn't exist, the default of 16 bits / 16 bits is used. |

The uniqueness of the product ID (and with it, the Unique-ID) is guaranteed by every vendor through the hardcoded serial numbers. Neither the unique ID nor the product ID constitute a fixed hardware identifier however, one and the same device can have several firmwares installed which may differ in their classes or even product types. Only the serial number remains the same normally, but on its own that is not necessarily unique.

Additionally, there might be a user string stored in the node (nick name, see MSG_STRING). This name can be used as alternative for the presentation of the node.

Connecting to a BiDiB system can be done according to the following list:

Nodes declare different classes via their Unique ID, e.g. occupancy detection, hub or booster functionality. To what extent a class is implemented is announced through feature settings.

For each class there are mandatory messages that have to be implemented, as well as optional messages that are only available if a feature declares them to be.

A BiDiB system has a global system time available to achieve a higher accuracy in time-based measurements. Various messages may contain a timestamp for the respective event, this allows for better results in vehicle tracking and calibration. The uncertainty in the latency of the data transmission is eliminated.

The BiDiB system time has a resolution of 1 millisecond and is represented by a 16-bit integer with cyclic overflow An error margin of ±5 ms between the clocks of all nodes in a system is aspired.

To facilitate a time measurement across different nodes, the clocks of the nodes have to be synced. This synchronisation happens on every bus level depending on the transport layer and is carried out by the respective interface. Whether an interface/hub does or not support it must be stated in the product description.

The synchronisation typically happens through a periodically emitted broadcast message with a timestamp. On the receipt of this message, the local node clock is set to the system time. Delays on the communication path or internally at the transmission and reception need to be considered and have to be corrected through according offsets, the arising inaccuracy should be ±1ms per bus level at most. With this approach a (small) step in the time series at the point of adjustment may occur, a host will need to take such into account.

If the synchronisation is absent, a node must refrain from the use of timestamps as soon as the resulting uncertainty becomes larger than ±3 ms. Example: if a processor clock rate has a divergence of up to 10ppm (0,01 ‰), then it should not use its local clock from about 100 s after the last synchronisation.

An interface should wait for synchronisation from the upper level before supplying the system time to its subnodes. If a synchronisation message fails to appear until the SYS_ENABLE (or a reasonable timeout), the interface may use its local clock time and synchronise the bus structure on its own.

The messages, which are used on the BiDiB system, can be divided into the following categories:

| System | Software and hardware version and product identification query, system start and -stop, connection settings, node address settings and queries. |

|---|---|

| Feature | Querying and setting of the node properties (features). |

| User-Config | Open messages for advanced, vendor-specific configuration. |

| Messages for firmware updates | Uploading of new node software. |

| Messages for Detectors | Occupancy reports and decoder feedback |

| Messages for Booster | Monitoring of boosters |

| Messages for command stations | DCC motion and switch commands |

| Messages for accessory control | Turnouts, signals, track system functions |

| Messages for configuration and direct port control | Illumination, animations, sound, peripheral equipment |

| Local messages | Link establish, synchronisation, link control |

Downlink describes the direction Host -> BiDiB-System, uplink means the direction to the host.

In general, messages occur spontaneously at the uplink (after approval at the interface). Some messages types can be switched on or off by feature settings.

For local communication inside a specific bus level further messages may be used for link control, logon/logoff or time synchronisation.> Depending on the topology and used physical layer a different set of local messages may be required, governed by the respective transport layer specification.

The message type ranges 0x70 to 0x7F (downstream) and 0xF0 to 0xFF (upstream) are reserved for local messages. This allows the partitioning and separate handling of these messages on the link layer.

Local messages are categorically exempt from sequence numbering to not interfere with the index progression of the overarching connection between host and target node. They are transmitted with sequence number 0. On reception, it is not evaluated and the receive-counter is not modified.

System messages are mandatory for all standard BiDiB nodes, only exception are bootloader nodes, see MSG_SYS_MAGIC for more details.

Common system messages

The addressed BiDiB Node should transmit the system identifier. No other data will follow. This message shall be send prior any other request to the node.

The node responds with its SYS_MAGIC, which also codes the general behaviour of the node.

Query for the supported BiDiB protocol version. No other data will follow.

The corresponding node responds with the version of the protocol supported by its software.

No other data will follow. The node will be released, from now on, spontaneous messages are possible (e.g. change of occupancy states, new added hardware). The message is automatically passed to all other subnodes (inherited). No acknowledgement will follow.

The BiDiB system will be blocked, spontaneous messages are disabled at this point. Events which occur in the SYS_DISABLE state will not be cached, yet node states can be queried targeted. The message is automatically passed to all other subnodes (inherited) and should therefore be addressed only to node 0. No acknowledgement will follow.

Query for the Unique-ID and configuration fingerprint of a node. No other data will follow.

The corresponding node responds with MSG_SYS_UNIQUE_ID.

(The Unique-ID of a node is also stored in the node table of its interface).

Query of the node's installed software version(s). No other data will follow.

Followed by one byte.

The corresponding node in the BiDiB system is initiated to send an empty message (MSG_SYS_PONG) back. This response must be received within 250 ms, otherwise the host has to consider the corresponding node as failed. The passed parameter (byte) is returned by MSG_SYS_PONG.

No other data will follow.

The corresponding node in the BiDiB system is initiated to send a message of type MSG_LOCAL_PONG back. This response must be received within 250 ms, otherwise the host has to consider the corresponding node as failed and transmit this failure with MSG_NODE_LOST to the host.

(In case of BiDiBus, the token and the answer to that token takes over this function.)

Followed by one byte: Identify is switched off, 1: Identify is switched on.

The corresponding node in the BiDiB system is instructed to display a local identify indicator (e.g. a flashing LED). The node responds with a MSG_SYS_IDENTIFY_STATE message.

The last occurred (but not any spontaneous) error message is read. The error memory is cleared through reading. If there is no error, an empty error message (i.e. error number 0) is returned.

Followed by two bytes (TIMEL, TIMEH) with the BiDiB system time, TIME indicates the point in time of the last frame marker prior to the message. The node sets its local clock to the received timestamp, possible data transit times must to be compensated by corresponding offsets. The message is not replied to.

Example: A node receives MSG_LOCAL_SYNC 3. The duration from the frame signal to the processing of the message amounts to 2 ms. The internal clock will be set to 5.

System messages for bus management

Hints for implementation: this messages are mandatory, but these messages include only variable data at interface nodes. Simple nodes have constant data. This means the answers to MSG_NODETAB_GET* etc. can be stored as constants and can be implemented also on very small microcontrollers. BiDiB has an automatic node assignment (e.g. detector, booster, etc.). This mapping is stored in the interface and can be collected from there. For this purpose, the following messages are provided:

The BiDiB system will be reset with regard to the host interface and the allocation of all nodes is carried out again. The previous assignment table is void.

All message sequence numbers in the upstream will be set back to zero but the function of the node remains.

If this message is addressed to a node, it shall log off (ie. shutdown for 1s, the interface will drop the node) an try to reconnect again. Internal states of the node may be lost.

With this command, the interface is caused to transfer the current assignment table of Unique-ID and local address. This transfer is a series of messages, it is started with a MSG_NODETAB_COUNT and will be followed by MSG_NODETAB, each of which are triggered by MSG_NODETAB_GETNEXT.

While the transfer is in progress, new inquiries with MSG_NODETAB_GETALL lead to abortion and restart of the transfer.

If the table does not yet exist, the interface responds with a MSG_NODETAB_COUNT = 0 message. In this case, the host must ask for it again after a few ms.

If the table is existing, the interface responds with MSG_NODETAB_COUNT = 'table length'.

This command causes the interface to send the next line of the node table. No parameters follow.

The node responds with a MSG_NODETAB message. In case there is no (more) line on hand, it responds with MSG_NODE_NA 255 instead. If there was a change in the node table since the last transmission of MSG_NODETAB_COUNT, the node responds with MSG_NODETAB_COUNT and starts over with sending MSG_NODETAB messages (with the incremented version number).

With this command, it is possible to read in the maximum message length that a node can handle. This corresponds to the maximum length of a message sequence when it consists of only one message, and thereby the maximum number of bytes in a packet (between two frame markers).

The node responds with a MSG_PKT_CAPACITY message. Until a node responds with a value above 64, the default restriction to 64 is in effect.

Followed by one byte with the confirmed sequence number (version number of the node table) of NODE_NEW or NODE_LOST message. The host sends this message within 250ms to an interface when he received a notification for a lost or newly added node. If the interface gets the same version of node table that it has sent in the last change notification, this and all previous changes are considered as acknowledged.

Followed by one byte with the local address (NODE_ADDR) and 7 bytes with the Unique-ID. Only if the node has verified that the received Unique-ID and the internal Unique-ID is identical, he may set his local address to received NODE_ADDR.

This message will be sent as broadcast and with MNUM = 0. It is always interpreted, even if no login attempt was made. It is therefore possible to assign a local address to a node before the general logon.

Followed by 7 bytes with the Unique-ID. The logon attempts of the addressed node are refused.

Possible causes for the rejection of the LOGON can be:

Simultaneously with the MSG_LOCAL_LOGON_REJECTED, the interface sends an error message with BIDIB_ERR_BUS to the host.

System messages for layout management

(Hints for implementation: this messages are mandatory)

This command transmits a model time for layout appliances. This clock typically runs accelerated compared to the real time. Followed by 4 bytes (TCODE0, TCODE1, TCODE2, TCODE3) with the time value. The coding of these bytes is the same as the coding of the corresponding DCC command.

| Field | Encoding | Meaning |

|---|---|---|

| TCODE0 | 00mmmmmm | mmmmmm = Minute indication, value range 0…59. |

| TCODE1 | 100HHHHH | HHHHH = Hour indication, value range 0…23. |

| TCODE2 | 01000www | www = Weekday, 0=Monday, 1=Tuesday, ... 6=Sunday. |

| TCODE3 | 11ffffff | ffffff = Clock acceleration factor, ffffff=0 means clock is stopped. |

Every field consists of a 2-bit type and 6-bit value. The host sends the complete time package every model-minute.

Is the system is stopped, the clock factor 0 should be sent.

On bus implementations, this message should be preferably send as broadcast.

Common system messages

Transmission of the system identifier: This variable is used for identification and transmission control. Followed by 2 data bytes, MAGICL, MAGICH which indicates the system identifier. The system identifier is transmitted with a transmission sequence index 0, this restarts the synchronisation of message sequence at host side.

| MAGICL | MAGICH | Description |

|---|---|---|

| 0xFE | 0xAF | BIDIB_SYS_MAGIC = Regular BiDiB Node |

| 0x0D | 0xB0 | BIDIB_BOOT_MAGIC = reduced bootloader |

| … | … | reserved |

If a node responds to MSG_GET_SYS_MAGIC with BIDIB_BOOT_MAGIC (=0xB00D), this node has a very reduced functionality support only some commands (see table) and firmware update (bootloader). The node doesn't know any features and will not respond to feature queries. However, the feature FEATURE_FW_UPDATE_MODE (254) is equal 1 (although it isn't queriable). Also the fault detection and treatment is reduced in this node, but the check of the integrity of the data transmission (CRC) is still mandatory. The node hasn't set any ClassID bits.

| Downstream | Upstream |

|---|---|

| MSG_SYS_GET_MAGIC | MSG_SYS_MAGIC |

| MSG_SYS_GET_P_VERSION | MSG_SYS_P_VERSION |

| MSG_SYS_GET_SW_VERSION | MSG_SYS_SW_VERSION |

| MSG_SYS_IDENTIFY | MSG_SYS_IDENTIFY_STATE |

| MSG_FW_UPDATE_OP | MSG_FW_UPDATE_STAT |

| MSG_SYS_RESET | |

| MSG_LOCAL_LOGON_ACK | MSG_LOCAL_LOGON |

| MSG_SYS_GET_UNIQUE_ID | MSG_SYS_UNIQUE_ID |

Followed by one byte. This message is a response to the MSG_SYS_PING request, while the transferred byte in PING will be sent back.

Empty message, no other data will follow. This message is the response to MSG_LOCAL_PING.

Transmission of the supported protocol version. Followed by 2 data bytes which encode the BiDiB protocol version.

| Parameter | Description |

|---|---|

| P_VERSIONL | Minor protocol version number |

| P_VERSIONH | Major protocol version number |

The node sends its unique identifier. Followed by 7 bytes with the Unique-ID and optionally 4 bytes with a configuration fingerprint.

The fingerprint is a 32 bit checksum applied to all settings of the node. Those include:

Explicitly exempt are all bus and operation states (even those that are persisted across power cycles), supported protocol versions and firmware revisions (assuming nothing else changes).

The fingerprint is computed by the node using a good (uniformly distributed, chaotic, efficient) but not necessarily cryptographic hash function. When a configuration value changes, the fingerprint changes as well.

Transmission of the software version: Followed by 1 to 16 triples (3 bytes each), vendor specific. Inside each triple the sub revision index is transmitted first, the main revision index is transferred last. Newer versions have a numerically larger version index.

The first triple denotes the software version of the node, additional triples may code the version of subsystems (like coprocessors, hardware).

Note: up to BiDiB specification revision 1.21 only one triple was defined as answer.

Followed by 1 byte with the identify status: 0: off, 1: on.

This message is sent when identification of the node was triggered, either by host command (MSG_SYS_IDENTIFY) or locally by the identification button.

Recommendation: If the identify button is assigned to more than one function (e.g. if a decoder can also be programmed via DCC address-learning), a short press should execute identify, a long press should execute the DCC learning mode. This recommendation ensures the same behaviour across different modules.

Error message of a node. The errors take place either by a query (by MSG_SYS_GET_ERROR) or spontaneous (if the node is enabled). Followed by one byte with the error type and occasionally other parameters. Depending on the error, the processing of the data will not be possible any more.

| Value | Name | Meaning | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0x00 | BIDIB_ERR_NONE | The node has no errors (any more) in the fault memory. | ||||||||||||||

| 0x01 | BIDIB_ERR_TXT | The node sends a text error message: followed by one byte with the length description, followed by ASCII-characters of the error message. | ||||||||||||||

| 0x02 | BIDIB_ERR_CRC | The received message (or the message packet) had a CRC error,

followed by one byte with the MSG_NUM of the faulty message.

The node discards the received message packet. Note: this error message is only useful on point-to-point links. On implementations with broadcasted messages, the receiver should not response with an error message (only discard the received data). | ||||||||||||||

| 0x03 | BIDIB_ERR_SIZE | The received message has too small length (too few parameters). Followed by one byte with the MSG_NUM. The node discards the received message. | ||||||||||||||

| 0x04 | BIDIB_ERR_SEQUENCE | The received message sequence has an sequence error, messages have been lost. Followed by one byte with the expected MSG_NUM (if there had been no sequence error) and optionally one byte with the MSG_NUM of the current message, i.e. the first one that was correctly received again. However, the node processes the received messages and the current sequence number is taken over as the new starting point. | ||||||||||||||

| 0x05 | BIDIB_ERR_PARAMETER | The received message has an parameter error. Followed by one byte with the MSG_NUM of the message which contains the error. The message is not processed. | ||||||||||||||

| 0x10 | BIDIB_ERR_BUS | The sub-structure associated to this node has a bus error.

Followed by one byte with the fault code:

| ||||||||||||||

| 0x11 | BIDIB_ERR_ADDRSTACK | A message from a sub-node contains 3 local addresses, i.e. the available address stack is fully utilized

(because there are too many levels in line). The message can not be routed any more. Followed by 4 bytes: NODE ADDR_STACK NODE: the node, which has submitted the too long address. ADDR_STACK: The remaining bytes of this address. With this data, the host can identify the level in which the address violation occurred. | ||||||||||||||

| 0x12 | BIDIB_ERR_IDDOUBLE | A node is trying to log on which already is logged on

or which has the same ID as one that already is present in the node table. Optional followed by 7 bytes with the Unique-ID of the node. | ||||||||||||||

| 0x13 | BIDIB_ERR_SUBCRC | A message from a subnode was not received because of an CRC error. Followed by 1 byte: NODE NODE: Local address of the currently addressed node. | ||||||||||||||

| 0x14 | BIDIB_ERR_SUBTIME | A message from a subnode was not full received because of an timeout. Followed by 1 byte. NODE NODE: Local address of the currently addressed node. | ||||||||||||||

| 0x15 | BIDIB_ERR_SUBPAKET | A package with a message from a subnode had a consistency error in the size specification. Followed by 1 byte with the NODE-address and optional further bytes with the contents of the data package. NODE: Local address of the currently addressed node. | ||||||||||||||

| 0x16 | BIDIB_ERR_OVERRUN | An interface could no longer relay all transferred messages to its sub-structure, messages have been lost. | ||||||||||||||

| 0x20 | BIDIB_ERR_HW | The node has detected an internal error. Followed by 1 byte with the error number (vendor specific) | ||||||||||||||

| 0x21 | BIDIB_ERR_RESET_REQUIRED | The node requires a reset. Ie there was reconfiguration which gets valid after a reset. | ||||||||||||||

| 0x30 | BIDIB_ERR_NO_SECACK_BY_HOST | The maximum number of occupancy message repetitions was reached without the host having mirrored the status. |

System messages for bus management

(Note about implementation: These messages are for interface nodes with variable data, simple end nodes have constant data, corresponding responses can therefore be statically stored in the processor flash memory).

This message is sent prior to the transmission of individual MSG_NODETAB, if the host has requested with MSG_NODETAB_GETALL. Followed by 1 byte with the node table length. This table is fetched with a corresponding number of MSG_NODETAB_GETNEXT queries.

Followed by 9 bytes with an entry of the node mapping table:

| Parameter | Description |

|---|---|

| NODETAB_VERSION | Current version of the table, will be incremented at each change, overflow: 255→1 |

| NODE_ADDR | Assigned local address of the node (value range 0…127) Address 0 represents the node itself. |

| UNIQUE_ID[7] | The Unique-ID of the node, consisting of 7 bytes |

If a node has no subnodes (no class bit 'Hub' is set in the Unique-ID), the node table has only one entry length and contains the node itself.

The transmission of the node table is done by one or more MSG_NODETAB messages. While transfer is in progress, no nodes should be added or removed from the table. If a change happens nonetheless, the interface must start over again with the transmission of a new MSG_NODETAB_COUNT.

With this message, a node reports the maximum message length that it can locally handle. This is generally restricted by the size of the receive buffer for packets of the respective transport layer (which is otherwise transparent towards the host). For packet based transmission of message sequences, the length corresponds to the maximum number of bytes for the packet content (as a sequence of only one message), e.g. 64 at BiDiBus.

Followed by a length designation, consisting of 1 byte, value range 64…127. The minimum value is 64, smaller values are reserved and to be ignored. (MSB is reserved for length-extension)

Followed by a byte with the (local) number of the addressed node. The message is rejected from the interface and will be returned if the host attempts to contact a node, which is not (or no longer) in the list.

This message will be (with node 255) also sent, if all nodes has been already transferred by MSG_NODETAB_GETNEXT.

Followed by the current version number of the node table and the table entry of the lost node (see MSG_NODETAB), consisting the local address (1 byte) and the Unique-ID (7-bytes).

An already registered node does not respond any more. If (for example) the lost node is an detector, the host can (and should) take appropriate action (partial or general emergency-stop, traffic control). The MSG_NODE_LOST must be confirmed by the host. If this message will not be confirmed within 250 ms, the interface repeat it at a maximum of 16 times.

A new, not yet existing node is detected and added to the node list. Followed by the current version number of the node table, and the table entry of this new node (see MSG_NODETAB) consisting of local address (1 byte) and Unique-ID (7-bytes).

The messages for MSG_NODE_LOST and MSG_NODE_NEW will be sent only after the first reading of the node table and only if the (spontaneous)-enable at the interface is activated. MSG_NODE_NEW must be confirmed to the host, as well as MSG_NODE_LOST. This is done with MSG_NODE_CHANGED_ACK or a complete query beginning with MSG_NODETAB_GETALL, otherwise up to 16 repeats take place.

If multiple changes occur in succession, the version number is incremented each time and a message is generated, but only the last change will be repeated.

Followed by a byte which identifies the status.

| 0: | The node operates normal |

| 1: | A node sends this message if he detects that his output data buffer is going to be full and therefore the current downstream message can not be handled. Such a situation may occur if the host "deluge" the node with requests. STALL can also occur if e.g. a sublevel of an interface has a lower bandwidth: the interface node isn't able to forward all messages to its subnodes. In this case, the host shall not continue to send messages to subnodes this interface. |

A MSG_STALL=1 will be terminated from the node with a MSG_STALL=0.

Followed by 7 bytes with the Unique-ID. The node is trying to logon. This message is used at system start up in the process of assigning the local bus addresses.

Preamble: There are different implementation and requirements for a BiDiB system, which are also partially specific to the layout. In addition, nodes with different properties might be installed at the layout.

For this reason, there is the ability in the protocol to query properties of nodes and also to configure the node, this means to enable this property. This is done through the feature-settings. If a node does not support a particular property, then the corresponding feature-setting can not be changed. The host can control this by testreading the settings that have been made.

The answering for feature messages is mandatory for nodes, but features are not. The ID's for certain feature setting are mandatory. Not assigned feature IDs are reserved. Extensions for new features (new ID's) must be applied for at the BiDiB workgroup.

A complete list of all feature-ids can be found in bidib_messages.h.

| Number | Name | Meaning |

|---|---|---|

| 112 | FEATURE_CELL_NUMBER | (logical) reference mark of this node (used for wireless systems) 0: single system. 1…n: area mark of this emitter. |

| 113 | FEATURE_RF_CHANNEL | used RF channel 0…83: channel number in 2.4GHz band 84…255: reserved |

| 250 | FEATURE_STRING_NAMESPACES_AVAILABLE | Availability of string namespaces as a bitfield:

|

| 251 | FEATURE_STRING_DEBUG | Usage of string namespace 1. Range: 0 (off), 1 (mode for 7 text streams); Default 0. |

| 252 | FEATURE_STRING_SIZE | Maximum number of chars for string variables in namespace 0. Range: 0; 8…24 (If the feature FEATURE_STRING_SIZE is missing or its value is 0, the node can't handle the corresponding messages.) |

| 253 | FEATURE_RELEVANT_PID_BITS | Number of significant bits for the product ID (contained in the Unique ID). Range: 1…31. Default 16. (If the feature FEATURE_RELEVANT_PID_BITS is missing, the default 16 bits for product ID and 16 bits for serial number is used. |

This command is used to begin the query of all feature settings. Followed by an optional byte for requesting a streaming transmission. The node resets its internal counter for MSG_FEATURE_GETNEXT queries and responds with a MSG_FEATURE_COUNT, which specifies the number of existing features. If this number is 0, the node has no features.

If the optional parameter is set to value 1, this signals to the node that it should begin sending the feature messages without waiting for MSG_FEATURE_GETNEXT queries. The optional parameter with the value 0 signals that the host does not want the feature values to be streamed. The values 2..255 are reserved. Supporting this functionality is optional, but recommended for nodes from declared protocol version 0.8.

With this message, a feature value is queried. No byte will follow. The answer is either a MSG_FEATURE (the node itself selects and sends the respective next FEATURE) or a MSG_FEATURE_NA message (with feature_num = 255), if all features have been already submitted.

Query for a single feature. Followed by a byte with the feature number, which was queried.

The node responds with MSG_FEATURE.

Setting of a single feature. Followed by 2 bytes: feature number, value.

The node responds with a MSG_FEATURE as confirmation. If a value has been sent that is not adjustable, the actual value which was set is returned.

The encoding of feature sets for each class is provided in the documentation of the individual classes.

If a node is addressed with a unknown feature ID, a MSG_FEATURE_NA (= feature not available) will be returned.

For the answer to a query feature, the following message types are used:

Followed by 1 byte with the feature number and 1 byte with the value. Logical features are enabled at 1 and disabled at 0.

This message will be sent if a feature was requested that is not available on this node. Followed by 1 byte with the (not implemented) feature number.

This message is also sent (with feature number 255) in response to MSG_FEATURE_GETNEXT, if all features have already been transmitted.

This message is sent prior to the transmission if the host has made a request with MSG_FEATURE_GETALL. Followed by 1 byte with the number of the existing feature messages and optionally 1 byte for announcing the transmission mode.

The mode byte is set to the value 1 when the host requested streaming and the node supports it. The node begins sending the MSG_FEATURE on its own and is responsible for flow control, adjusting to the available transport capacity itself. The node must remain fully operable and be able to receive and respond to other messages during the transmission. The count allows the host to determine when all feature messages have arrived.

Otherwise, the feature values are polled individually using a sequence of MSG_FEATURE_GETNEXT. The count allows the host to make the suitable number of requests.

There are some vendor-specific parameters, which goes beyond the normal configuration. For this part of the protocol, only the transmission technique is defined, parameter name, content and meaning lie within the responsibility of the manufacturer.

Vendor-specific data transmissions may not be used for control, feedback and other commands, for which a counterpart is existing in the normal protocol.

Before these parameters can be transmitted, the corresponding node must be activated with its UNIQUE-ID. No other messages except VENDOR_** are allowed between VENDOR_ENABLE and VENDOR_DISABLE. Other requests are only allowed after the node has confirmed MSG_VENDOR_DISABLE.

Followed by 7 bytes of the previously read UNIQUE-ID. The node responds with a MSG_VENDOR_ACK.

No other data will follow; the node is disabled. The node responds with a MSG_VENDOR_ACK.

Followed by the data below, which are structured as follows:

VENDOR_DATA ::= V_NAME V_VALUE V_NAME ::= LENGTH V_NAME_STR V_NAME_STR ::= V_NAME_CHAR | V_NAME_CHAR V_NAME_STR V_VALUE ::= LENGTH V_VALUE_STR V_VALUE_STR ::= ε | V_VALUE_CHAR V_VALUE_STR

The node stores the parameter value in its configuration, in case the key (V_NAME) is known. It responds with a MSG_VENDOR message, this includes the same V_NAME and the saved value. When a problem appears during processing, the saved value may deviate from the value transmitted in MSG_VENDOR_SET, then usually the previously stored value is kept.

Followed by the data below, which are structured as follows:

V_NAME ::= LENGTH V_NAME_STR V_NAME_STR ::= V_NAME_CHAR | V_NAME_CHAR V_NAME_STR

The node responds with a MSG_VENDOR message, which contains the same V_NAME and the stored value of this parameter.

When the key (V_NAME) is not known to the node,

it responds with an empty value (V_VALUE = 0x00 "").

The node configuration is treated like an associative array (key-value pairs). V_NAME and V_VALUE are ASCII sequences, so that a user input can be directly forwarded to the node. When the sequence consists of digits 0…9, it represents a numeric value. The keys (V_NAME) should generally begin with a letter. The principle is similar to the entries in an INI file.

It is recommended to use descriptive names for the parameters and their values, but limit oneself to about 32 bytes of total length. A hard limit is given by the packet size, with a maximal message length of 64 bytes there remain 55 bytes for the two strings V_NAME_STR and V_VALUE_STR.

The classical CV programming is emulated with numeric values for V_NAME and V_VALUE,

the address range begins at 1 (as usual in decoder manuals).

V_NAME = 0x01 "0" is invalid.

MSG_VENDOR_GET 0x01 0x38 (=1 '8'): CV 8 (vendor ID at normal decoders) will be read:

1 is the length of the string, which consists only the ASCII-character for 8.MSG_VENDOR_SET 9 'T'H'R'E'S'H'O'L'D' 3 '2'5'5':

The message begins with the identifier MSG_VENDOR_SET,

followed by a length byte of 9 and the parameter name 'THRESHOLD',

further followed by another length byte (3) and the parameter value (255).This message type is used to send a string value to a node. This command is followed by data denoting the addressed namespace, the addressed identifier (variable to be set, channel), the string size and the string itself.

This function is only available in a node if announced by the respective feature.

| Parameter | Description |

|---|---|

| NAME_SPACE | denotes the addressed namespace inside the node, range 0…255

|

| STRING_ID | denotes the addressed string inside the given namespace. Namespace 0:

|

| SIZE | length of the string.

|

| CHARS | String, coded according to ISO 8859-1 (simple 8-bit coding). 0x00 is not allowed as string character. |

The node responds (for namespace 0 and 2) with MSG_STRING and the newly stored value. If the written string is longer than allowed, it is truncated by the node or the message is rejected with BIDIB_ERR_PARAMETER. If the response for a string results in the size 0, then the string doesn't exist.

\n is used as delimiter.

That way, also longer inputs or outputs can be transmitted, and multiple channels can be displayed line by line.

A sequence error in the transmission should be handled like a newline.Query of a string variable inside a node. Two bytes are following, denoting addressed namespace and string identifier. This function is only available in nodes if announced via the respective feature (FEATURE_STRING_SIZE, FEATURE_STRING_NAMESPACES_AVAILABLE).

The node responds with a MSG_STRING that contains the queried string. If a string doesn't exist, the returned SIZE is 0.

This message type is used for the answer to a userconfig. Followed by the data below, which are structured as follows:

VENDOR_DATA ::= V_NAME V_VALUE V_NAME ::= LENGTH V_NAME_STR V_NAME_STR ::= V_NAME_CHAR | V_NAME_CHAR V_NAME_STR V_VALUE ::= LENGTH V_VALUE_STR V_VALUE_STR ::= ε | V_VALUE_CHAR V_VALUE_STR

Followed by a date: 0: No user config-mode, 1: Confirmation that the node has changed into userconfig mode.

This message type is used as the answer to MSG_STRING_SET or MSG_STRING_GET. The message may also be sent spontaneously for namespace 1 once the node is enabled.

Followed by data denoting the used namespace, the string identifier, the string size and the string itself. Order and format of the parameters corresponds to MSG_STRING_SET, for details see there.

A module may change its unique ID after a firmware update but there are also modules available, which offer only firmware update function at the beginning. In this case, they log on normally but all class bits has been set to zero.

For troubleshooting or retrofitting new features, it is desirable that nodes have the ability to update their software. Whether and how the software of a node can be updated is determined by a feature.

The sequence of FEATURE_FW_UPDATE_MODE = 1 is shown in the following example:

At the end of the firmware update, the host sends a command to reboot or exit. The node acknowledges this message and waits for 1s (the interface logs off the node within this time), then the node restart and will be logged in automatically. It is recommended to implement specific actions within the firmware (e.g. CRC check at startup), to check the complete and correct transfer of the firmware.

As the node is freshly logging on to the BiDiB system, it's state for SYS_ENABLE is off. Therefore it may be required to notify the node after FW update with a MSG_SYS_ENABLE.

| Number | Name | Meaning |

|---|---|---|

| 254 | FEATURE_FW_UPDATE_MODE | 0: no firmware-update possible 1: firmware-update with Intel-Hex method possible. The maximum line length is 16 data-bytes (i.e. the intelhex-line starts with ':10' or smaller). |

Target memory areas:

Depending on the implementation of the nodes, different memory areas like Flash, EEPROM etc. can exist. For each of these target memory areas there will be a single update file from the manufacturer.

For update-files a consistent naming scheme has been set out:

| Placeholder | Substitution |

|---|---|

| name_version | name of the firmware, this name should show the manufacturer and product in a recognizable way. Furthermore it should show the firmware version. All files for different target memories must use the same string for name_version. |

| ddd | Target memory area, 3-digit, filled in with leading "0". |

| hex | file extension, the fixed extension .hex will be used. |

xyz_occupancydetector_v1_23f.000.hex xyz_occupancydetector_v1_23f.001.hex

000 and 001 is the corresponding number of the destination memory area in this example. It is recommended to use 000 for the main program memory and 001 for the configuration memory (EEPROM).

Also here, a strict handshaking applies: Every message from the host must be confirmed by the node. New messages can be sent only when the confirmation of the previous message is present. This is due to occasional storage periods in which the node writes into the flash memory and, therefore, is not capable to execute normal program code.)

It is followed by another byte which indicates the desired operation. Depending on this byte, further paramters may follow.

The node responds with a MSG_FW_UPDATE_STAT.

| Value | Name | Meaning |

|---|---|---|

| 0x00 | BIDIB_MSG_FW_UPDATE_OP_ENTER | Node should switch to update mode. 7 byte will follow with the Unique-ID of the node. Only if the Unique ID matches with the node, the node will switch into update mode. The node responds with MSG_FW_UPDATE_STAT(BIDIB_MSG_FW_UPDATE_STAT_READY), if he succesfully changed into his boot-loader, or with MSG_FW_UPDATE_STAT(BIDIB_MSG_FW_UPDATE_STAT_EXIT), if he could not go into the boot-loader. |

| 0x01 | BIDIB_MSG_FW_UPDATE_OP_EXIT | Node shall exit the update mode. |

| 0x02 | BIDIB_MSG_FW_UPDATE_OP_SETDEST | Select target memory. With this command, the target area is defined,

in which the following data should be stored.

It is followed by a byte with the number of the target range. 0: Flash (Application) 1: EEPROM |

| 0x03 | BIDIB_MSG_FW_UPDATE_OP_DATA | Data: A data set will be send for the currently selected target memory. The data will be transmitted as a line of Intel Hex file. 'White'-Characters (0x20, 0x09, 0x0D and 0x0a) will not be transmitted. |

| 0x04 | BIDIB_MSG_FW_UPDATE_OP_DONE | No more data available for the currently selected target memory. Node shall perform the update of the target memory. |

After a MSG_FW_UPDATE_OP command, a status message will always be send. Followed by 2 Bytes:

| Parameter | Description | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STATUS | Process state

|

|||||||||||||||||||||||||||

| TIMEOUT or ERROR |

After a successfull execution, this byte indicates the minimum time that the host

needs to be wait until the next packet can be sent:

|

Track-output devices are nodes with the ability to generate a DCC-signal. This DCC signal is by default only known by the node itself and all directly connected devices. The node can be enabled through system messages in order to control the distribution of the DCC signal (via the corresponding line pair). BiDiB contains the ability to run different DCC systems in parallel. Possible applications for the above feature is e.g. a separate programming track, which can be operated independently of the main track or a separate DCC signal branch, which is used for switch accesories only.

A common problem on exhibition layouts are 'down' locos with contact problems. This locos are not able to receive commands and therefore they interrupt the operation. BiDiBus provides a fast information transfer via a separate channel which allows to receive a railcom acknowledgement from the loco. This information is received from the track-output unit and can be combined to one message if the corresponding loco is still in communication with the control station. If the control station detects a lost loco, it reports this information to the host.

During regular operation, the track-output device is addressed by the host. However, there might be the request that DCC generators can be addressed decentralized and also from the host. The already existing trade-off ('who controls the loco, who secures driveway'), becomes an additional conflict: which device receives an acknowledgement from the command and the successfull output to the track? In BiDiB, it is intended (in regular opration conditions) that local control devices (distributed handhelds and switch boards) sends their demands to the host. The host checks and filters occasional (i.e. no turnout operation in a reserved route) and issue the appropriate command to the track-output device. In regular operation, the track-output device acknowledges against the host.

Accident and test mode: Moreover, there might be situations in which the host is not able to provide desired commands, e.g. because the operating situation is not intended, the PC program has crashed or the PC is simply not connected. Direct local control is provided for this scenario (accident and test operation).

For this emergency operation, DCC generators are allowed to listen for loco control commands on local bus structures (e.g. BiDiBus) and execute these commands without acknowledge. This ability is controlled by a feature. If this feature is enabled, handheld commands (which are actually sent to the host) will be read from the track-output device in 'spy mode' and are being executed. With this solution, the trade-off (who controls) can be resolved. The host has the possibility to stop this 'spy mode' via the command MSG_CS_ALLOCATE and the handheld will be therefore 'locked out'. This handheld 'lock out' with the command MSG_CS_ALLOCATE is only valid for a limited time, therefore MSG_CS_ALLOCATE has to be repeated continuously. That guarantees a smooth transition between PC and handheld control, also driving without a PC is possible without further actions.

Watchdog: The track output is equipped with an optional connection monitoring for the event of an unexpected connection loss between host program and track output which result also in a lost of the locos controls. The host program must renew the ON-status at the command station in regular intervals via MSG_CS_SET_STATE (BIDIB_CS_STATE_GO). The feature FEATURE_GEN_WATCHDOG defines the interval until the status renewal must be made.

If the renewal doesn't take place within the time limit, the track output controller stopps all locos which are currently controlled by the host.

A host program must fetch the feature FEATURE_GEN_WATCHDOG in advance before controlling any locos and it must renew the ON-status accordingly.

Inquiry: When a control or monitoring host program meets a running track signal generator and doesn't reset it, it will want to know about the active vehicles. The MSG_CS_QUERY command and the accompanying MSG_CS_DRIVE_STATE answer allow such a query of addresses, formats and states.

| Number | Name | Meaning | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | FEATURE_GEN_SPYMODE | Spymode Here will be set if local control (monitoring of handheld messages) is allowed or not. 0: Monitoring not allowed. 1: Monitoring allowed in general, but might be disabled by MSG_CS_ALLOCATE. | ||||||||||||||||

| 101 | FEATURE_GEN_WATCHDOG | Host Monitoring 0: No monitoring (=no watchdog function). 1…100: host control program must repeat MSG_CS_SET_STATE(GO) permanently. The repetition must occur before FEATURE_GEN_WATCHDOG * 100ms is elapsed. default = 20, corresponding to 2s. | ||||||||||||||||

| 102 | FEATURE_GEN_DRIVE_ACK | Acknowledge for drive and programming commands – bit field: Bit 0 additionally activates level 1 (track output) | ||||||||||||||||

| 103 | FEATURE_GEN_SWITCH_ACK | Acknowledge for switch commands – bit field: Bit 0 additionally activates level 1 (track output) | ||||||||||||||||

| 106 | FEATURE_GEN_POM_REPEAT | Number of DCC PoM messages, which are generates for each PoM command to the command station 2: according to railcom specification (default). 3…8: larger number of DCC messages (for decoders, which are not fully spec conform). | ||||||||||||||||

| 107 | FEATURE_GEN_DRIVE_BUS | DCC-bus control (within BiDiBus) 0: Node receives DCC from BiDiBus 1: Node drives DCC at the BiDiBus | ||||||||||||||||

| 108 | FEATURE_GEN_LOK_LOST_DETECT | Track output detects and reports 'lost' locos 0: Lost locos will not be recognized or reported. 1: Lost locos will be recognized and reported. | ||||||||||||||||

| 109 | FEATURE_GEN_NOTIFY_DRIVE_MANUAL | The track output may have occasional local controls.

| ||||||||||||||||

| 110 | FEATURE_GEN_START_STATE | Initial state of generator after power up. 0: DCC is off. 1: DCC is on. | ||||||||||||||||

| 111 | FEATURE_GEN_EXT_AVAILABLE | Additional protocol features of the generator. The extensions are supported when the respective bit is set.

|

Followed by a byte with content 0. (= local bus address of the host)

The track-output node does not receive commands from any other local addresses. This lock is valid for 2 seconds and then expires by itself.

With this command, the state of the track output is set or queried. Followed by one byte which encodes the new state. The node responds with a MSG_CS_STATE.

Before first turn on, the speed settings of all locos should be checked resp. the loco stack should be cleared. This avoid unintentional driving of loco with speed settings from a previous session.

| Value | Name | Meaning |

|---|---|---|

| 0x0 | BIDIB_CS_STATE_OFF | Track output will be switched off. As a consequence, also all connected boosters will be turn off. |

| 0x1 | BIDIB_CS_STATE_STOP | All locos will be stopped by an emergency stop, turnouts may still be operated. If stop is not supported by the control station, then OFF will be executed. |

| 0x2 | BIDIB_CS_STATE_SOFTSTOP | All locos will be stopped with speed step 0 (with their own delay),

turnouts may still be operated.

If soft-stop is not supported by the control station, then STOP will be executed. The track-output device execute the soft-stop and changes over to STOP mode afterwards. |

| 0x3 | BIDIB_CS_STATE_GO | Resumption of operation, locos and turnouts can be operated. If the watchdog-feature is enabled, this command must be repeated in the given interval by host program. |

| 0x4 | BIDIB_CS_STATE_GO_IGN_WD | Resumption of operation, locos and turnouts can be operated. A watchdog event will be ignored. |

| 0x8 | BIDIB_CS_STATE_PROG | Programming mode; the control station has switched over to programming mode and is ready to execute programming instructions (on the programming track). Normal operation is not active. |

| 0x9 | BIDIB_CS_STATE_PROGBUSY | Programming mode; This message indicates that there is currently a programming operation is active at the programming track. (only on request). |

| 0xD | BIDIB_CS_STATE_BUSY | The track output is not able to receive new commands, e.g. because corresponding output FIFOs are full. (Message only on request) |

| 0xFF | BIDIB_CS_STATE_QUERY | The state is queried. (only for MSG_CS_SET_STATE). |

Motion commands will be issued with this command. Following by further parammeters, which contains format and output functions. If an loco has no higher functions, the appropriate groups of the function commands should be marked as inactive. This conserves the limited bandwidth at the track.

MSG_CS_DRIVE commands will be acknowledged by one or more MSG_CS_DRIVE_ACK messages. The various acknowledgement levels can be activated in the output unit via FEATURE_GEN_DRIVE_ACK. If multiple commands for the same DCC address are issued, the output device is allowed to combine them in case of low bandwidth. In this case, intermediate acknowledgements can be omitted.

Motion commands will be passed always with the step number of 127 + direction bits. Only the track-output unit converts this motion command to the appropriate speed-step on the track depending from the selected format.

| Parameter | Description | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ADDRL | Address, lower 8 Bits. | ||||||||||||||||

| ADDRH | Address, upper 6 Bits. The complete address is given by ADDRH*256+ADDRL. The address designates the real (DCC) address and is counted from 0. Address 0 is not assigned to a specific loco and has a special role. (3) (4) | ||||||||||||||||

| DATA0 | Bitfield

| ||||||||||||||||

| DATA1 | Bitfield output active

If all bits are set to 0, then the loco will be removed from the repeat-memory at the output device (2), this is acknowledged with ACK=1. | ||||||||||||||||

| DATA2 | Speed, consisting of direction (MSB) and velocity (7 LSBs) (1) | ||||||||||||||||

| DATA3 | FL, F4 – F1; 3 MSB is reserved. The bit order of the function bits is: 3*reserved, FL (Light), F4, F3, F2, F1 | ||||||||||||||||

| DATA4 | F12 – F5 | ||||||||||||||||

| DATA5 | F20 – F13 | ||||||||||||||||

| DATA6 | F28 – F21 |

Accessory items will be controlled with this command. Followed by 4 bytes: ADDRL, ADDRH, DATA, TIME

The accessory decoder with address [ADDRH * 256 + ADDRL] is driven by the term in DATA. DATA is a bit structure, constisting of CONFIG (Bit 7,6) ACTIVATE (Bit 5) and ASPECT (Bit 4 – Bit 0).

| Parameter | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ADDRL | Address, lower 8 bits. | ||||||||||

| ADDRH | Address, upper 3 bits. The complete address is given by ADDRH*256+ADDRL. The address designates the real (DCC) address and is counted from 0. | ||||||||||

| DATA | Bitfield

| ||||||||||

| TIME | Switch time, given like the specification of railcom.

|

There is a multi-level acknowledgement mechanism for accessory commands too. Its levels can be activated via FEATURE_GEN_SWITCH_ACK. The node sends the respective MSG_CS_ACCESSORY_ACK messages.

Note: This message targets accessory decoders connected to DCC. It is recommended to directly connect accessories to BiDiB. These use the messages for class accessory and offer more features.

Programming commands for the main track (Program On Main) will be issued with this command. Followed by other parameters that describe address, selected CV, data and operation to be performed. Programming commands will be acknowledged by one or multiple MSG_CS_POM_ACK messages. The various acknowledgement levels can be activated in the output unit via FEATURE_GEN_DRIVE_ACK. If a track output unit can not issue a command (e.g. because the operation is not implemented), it sends a MSG_CS_POM_ACK with ACK=0 nonetheless.

If a Railcom-capable decoder answered the POM command, the appropriate bidi detector generates a MSG_BM_CV or MSG_BM_XPOM message.

POM commands are available in several variations, with the following key differences:

The parameters of the command MSG_CS_POM will always be encoded with the maximum field size, even if only short CV's will be addressed. Therefore, the address field is always 8+32 bit, the CV address field is 24 bit and the data field is 32 bit wide. As customary in BiDiB, the LSB will be transmitted first (little-endian).

| Parameter | Description | ||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ADDRL | Address, lower 8 bits (DID0 at decoder addressing). | ||||||||||||||||||||||||||||||||||||||||||

| ADDRH | Address, upper 8 bits. The complete address is given by ADDRH*256+ADDRL. The address designates the real (DCC-)address and is counted from 0. (DID1 at decoder addressing); The distinction whether a accessory or loco decoder is addressed, is encoded in bit 14 and 15:

| ||||||||||||||||||||||||||||||||||||||||||

| ADDRXL | 0 at loco addressing, DID2 at decoder addressing | ||||||||||||||||||||||||||||||||||||||||||

| ADDRXH | 0 at loco addressing, DID3 at decoder addressing | ||||||||||||||||||||||||||||||||||||||||||

| MID | 0: Addressing via loco address 1…255: Addressing via decoder ID, then this field is the manufacturer ID (=DID4) | ||||||||||||||||||||||||||||||||||||||||||

| OPCODE | Byte, defines the operation to be performed

| ||||||||||||||||||||||||||||||||||||||||||

| CVL, CVH, CVX | CV-Address, low byte first. CVX is only required with XPOM and will be transferred as 0

for classic POM. CV starts counting at 0 (same as track the command).

The CV naming of decoders starts at CV1 (CV1 will be coded with 0). For Short Form CV Access, this field directly sets the 4-bit Instruction Type, with the following values:

| ||||||||||||||||||||||||||||||||||||||||||

| DATA[1…4] | CV values. For standard POM there is only one datum, for XPOM write there are up to 4 data bytes. |

With this command, individual actions can be triggered at the decoder, e.g. activate coupling or analogue functions. Followed by 5 bytes: ADDRL, ADDRH, STATEL, STATEH, DATA. STATE denotes the type of DCC message.

| Parameter | Description | ||

|---|---|---|---|

| ADDRL | Address, lower 8 bits. | ||

| ADDRH | Address, upper 6 bits. The complete address is given by ADDRH*256+ADDRL. The address designates the real (DCC-)address and is counted from 0. Address 0 is reserved. | ||

| STATEL | Binary state number, lower 8 bits | Function control with group commands (RCN 212 2.3.1-4) 0: reserviert. 1: functions F1…F4, F0. 2: functions F5…F8. 3: functions F9…F12. 4: functions F13…F20. 5: functions F21…F28. 6: functions F29…F36. 7: functions F37…F44. 8: functions F45…F52. 9: functions F53…F60. 10: functions F61…F68. |

Analogue Channel (RCN 212 2.3.8), range 0…255 |

| STATEH | Binary state number, upper 7 bits. MSB is 0. | 0x80 (Opcode 0, MSB is 1). | 0x81 (Opcode 1, MSB is 1). |

| DATA | Binary state condition. Value range 0,1 | Bit vector with the functions as in the table above, first named function in LSB. range 0…255 | Analogue value, range 0…255 |

Binary states include 32767 possible outputs, they will be transmitted on the track together with the date D in 2 bytes: DCC codes this as DLLLLLLL HHHHHHHH. The Binary state number 0 means the addressing of all binary states in the decoder.

Functions and analogue values are output once (with standard repeat count) to the track, they are not recorded in the command repeat memory. If a function command is already present in repeat-memory (ie from a previous MSG_CS_DRIVE), the value in there is updated.

The support for analogue function commands and function groups up to F68 is announced in the FEATURE_GEN_EXT_AVAILABLE.

MSG_CS_BIN_STATE commands will be acknowledged with a MSG_DRIVE_ACK (same as for motion commands).

A query of active vehicles is performed with this command. Followed by 1 or more bytes encoding the query: QUERY[, ADDRL, ADDRH]

| Parameter | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| QUERY | ENUM of queried information and query mode:

| ||||||||

| ADDRL | Adress, lower 8 bits. | ||||||||

| ADDRH | Adress, upper 6 bits. The complete address is given by ADDRH*256+ADDRL. The address designates the real (DCC-)address and is counted from 0. Address 0 is reserved. |

The support of the generator for this command is determined by the FEATURE_GEN_EXT_AVAILABLE.

Service mode commands (at programming track) will be issued with this command. These track commands are only supported from output units with enabled class bit 3.